Examine any pair of boots on the shelf at a store and it’s easy to forget that there are people behind every stitch, tread and grommet. We got in touch with a few designers at KEEN, Miroslav Milanov, Anna Smith, and Cesar Geronimo, to learn more about the process of building a boot.

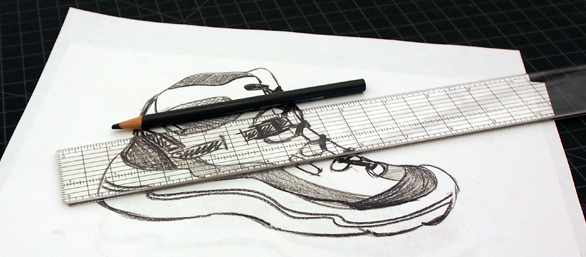

What is the first step you take when creating a new boot?

It always begins with some nugget of consumer insight — something we see on the trail, or a trend that indicates a change in the way people use their gear, or maybe a new way of approaching an activity. If there is a new or interesting problem to solve, we will try to create products that can do that or make the experience better.

Do you work off a standard template, or is it a ground-up creation?

We have some basic principles that guide our brand, including comfort, protection and durability, but it’s not a template just simply some values that we go to when beginning a new project. Beyond that, we like to let the consumer or activity define how the product will look and feel.

What is your favorite boot material?

I love a good leather boot. There are a lot of advancements in textile technology out there, but for me personally, the patina, the ‘muscle memory’ if you will, that leather takes on is one of the most beautiful things in the world. It’s what makes the shoes yours. There is no erasing, there is only accepting and moving forward.

How much of a role do new materials and manufacturing processes play into your design of boots?

Huge. The same footwear silhouette can be made up in many different variations of materials, which changes the look and function of the boot. We are always on the lookout for new materials or new ways of using known materials.

One of our newest styles, UNEEK, is a perfect example of taking an unconventional approach to some common material and creating an extraordinary different product. (See GearJunkie’s coverage of the UNEEK introduction.)

What kind of material would you invent if you had a magic wand?

Maybe material that can change densities with the temperature outside… I think they are working on that though!

What is your goal when setting out to create a new boot model?

We strive to design the best functional and best looking boot, which fits into the frame of the project at hand. One of the primary goals for us at KEEN is to always try and make the person’s experience with our product better.

Do you try to imagine the user in a specific setting?

Always. You want to design a boot that is functional, not just good looking. You think about how the person will be utilizing the boot, and then you design elements into it that will help them approach and accomplish the task. Aesthetics follow function.

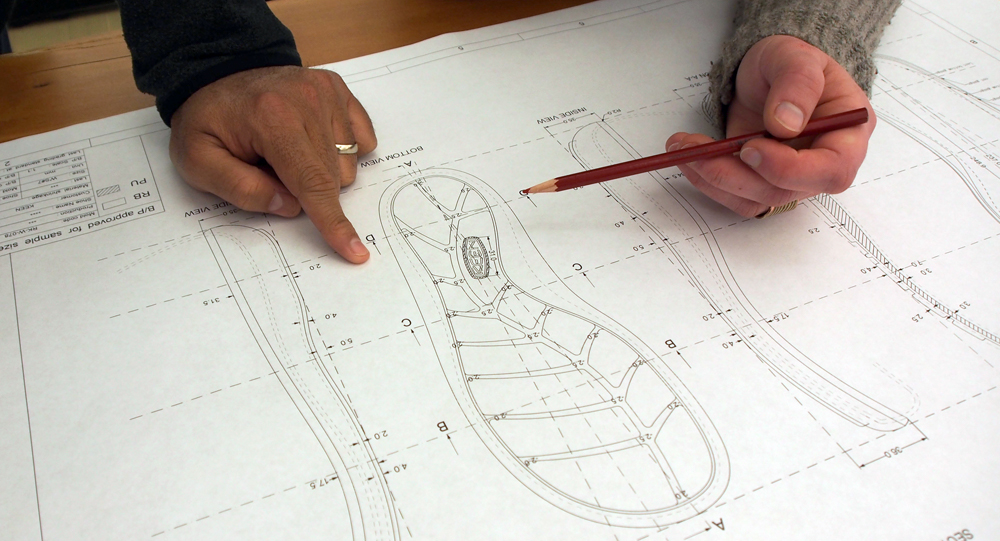

What kinds of tests do boots go through before heading into production?

It really depends on how they are intended to be used in the wild. Hiking boots have hundreds of miles put on them on various types of terrain before production; casual and utility products are both subjected to usage in their intended environment as well.

What are a couple simple things that a consumer should look for when buying a new boot?

Specific to hiking look for two things: Ankle protection without restriction, and underfoot comfort. Also, aesthetically, the less bulk the better.

What is the most exciting recent project you’ve worked on?

Many of us are most excited about the American-built products that we have launched in the last couple seasons, and the new ones we are developing now to be assembled here in Portland, Oregon. It’s very rare and special to make performance footwear in the U.S., and we feel like we are on the leading edge of a larger trend. Plus it’s just really cool to be able to travel 5 miles from the HQ building to see our designs come to life.

Why is KEEN building more of its footwear in the USA?

Why not? We have the drive and ability. It is a beautiful thing to have people be exposed to the process of manufacturing footwear. We’re heading into our fifth year of production and we couldn’t be more excited about the levels of quality, craftsmanship, and performance being delivered by our skilled crew right here in our own backyard of Portland, OR.

How much of KEEN’s boot manufacturing will shift to the U.S. in the coming years?

We’re excited to announce that more than 25% of our Fall/Winter 2015 hiking collection will be coming out of our Portland Factory!

How do you know when a boot is “done.”

From a product team point of view, nothing is truly ever “done” but when you are happy and feel that what you had set out to accomplish is done, then it’s time to leave it alone. We are always innovating, testing, tweaking, testing again and trashing ideas, but at some point you have to stop and finish it.

What is the future of footwear? What can we expect to see in 5 or more years?

The future will be driven by the innovation of new materials and processes. The design can be anything once you have the right tools you need at hand.

We anticipate that there will be a growth in products made coming from local markets such as the U.S. and Europe. They might heighten the emphasis on comfort, less weight, and offer a larger variety for the consumers in those markets. The future is simple, yet packed with function. It’s a very good time to be a consumer looking at new boots.

—Thanks to KEEN for sponsoring this post and offering its boot-fitting expertise. The Oregon-based company sells 20+ boot models, including built-in-the-USA footwear assembled in its Portland factory.