Skateboard manufacturing is dominated by wood laminate construction, but a California surfboard company is pushing the envelope with a high-tech manufacturing process called “crystal infusion” that injects resins into a mold of fiberglass and foam.

Hydroflex has developed a new honeycomb, composite construction that the company claims has no torsional flex, can be tuned, and is more responsive and durable than wood.

The boards are all manufactured in California. We haven’t had the chance to try them yet, but they look fun and the “crystal infusion” manufacturing process shown in this video is slick.

Hydroflex recently completed a successful Kickstarter campaign in which it raised almost $30,000, well beyond its goal of $15,000 to fund the project.

The boards are built using a patented 3D-glassing structure that multiplies the bonding surface for resins to adhere to, thus increasing strength between resin, cloth and core.

The bond makes the board strong enough to withstand the forces created by a skateboarder.

The company claims the board won’t lose flex and snap over time. Because the boards are not made from multiple layers of wood glued together, they will not warp or delaminate over time and are waterproof.

Hydroflex currently makes three boards, a micro cruiser called the Crilla ($90 deck, $170 complete); the mini cruiser Beach Leech ($110 deck, $190 complete); and longboard The Angler ($230 deck, $310 complete).

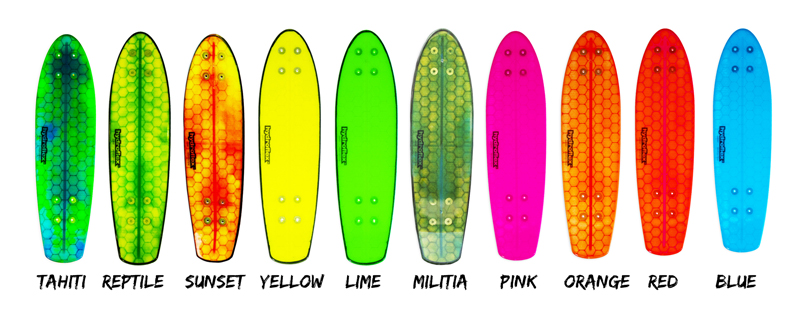

With a wide array of colors, there shouldn’t be any problem picking a favorite for a leisurely roll along the beach or a bomb down a smooth hillside. —Sean McCoy