Handmade in Oregon, a new line of sports helmets will eschew plastic and composites as protective shell material and instead rely on old-fashioned wood. Coyle Wood Design is run by Dan Coyle, a man with a personal interest in woodworking and outdoors sports. In the past, Coyle has built his own clothes, gear, paddles, helmets, and even eyeglasses by hand. With the helmet project, which will launch later this year, Coyle hopes to introduce a natural alternative to an industry dominated by ABS plastic and foam.

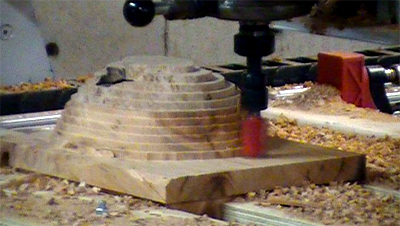

Coyle says he has spent significant time climbing, paddling, mountain biking, surfing, and canyoneering, and he has worn a plethora of different helmet types. His first wood prototypes were made for fun with a chainsaw and various hand tools. This year he got more precise with CNC machining tools, and he recently acquired a patent-pending status for “natural fiber helmet shells” products.

Coyle Wood Design has now built about 20 prototypes, and the outfit sees its wood line growing to include biking, paddling, snow sports, equestrian, and climbing helmet models. The process begins with prepping the pieces of wood and then CNC machining them for an hour or more. Coyle and his partners then take the “helmet blank” that the machine creates and begin a process of hand building, during which they are able to customize each helmet shell and change the profile shape or style.

Coyle and his team can change the brim, size of venting holes, helmet shape, and then add burned-on engravings to customize the helmet. “We hope that this will come to be recognized by folks as being as novel and exciting as the wood construction itself,” he said.

Safety and performance is a “huge subject” for the startup, Coyle said, and the company has a priority to validate its products. The company will seek certification in various sports (CE, Snell, CPSC) to assure safety of each helmet design.

For now, Coyle is working with the Oregon State University Wood Science and Engineering program to do impact studies with various materials. Based on existing material science data, Coyle said he believes he will be able to show that wood is a more effective energy-damping material than ABS, Mylar or other composites when used as a shell.

Wood type will vary on helmet type, Coyle said, and they may use softer woods that have mechanical properties similar to EPS foams for helmets designed for catastrophic impacts like those encountered biking and skiing. Harder woods with more durable grain patterns, such as burls, may be used for sports that demand “multi-impact durability” like climbing and paddling.

In addition to the lab work, Coyle Wood Design is beta testing its helmets with athletes so that it can “get feedback, make adjustments and then share these testimonials,” Coyle said.

Coyle believes there is a big market for the wood head-buckets, but he said he is “not driven to figure out how to sell a million of these.” Coyle continued, “I believe that finding ways to reincorporate natural materials into our everyday makes life a little richer.”

—Stephen Regenold is founder and editor of www.gearjunkie.com. Coyle Wood Design has a Facebook page and an under-development blog at coyledesign.wordpress.com.